RCO (Rubber Compound Oil)

RCO (Rubber Compound Oil) is an alternative fuel produced from the distillation of rubber without the addition of other additives. It is processed using a pyrolysis machine that converts the vapor from burning rubber waste into an alternative fuel oil through collection in a tank and filtration. RCO is similar to diesel fuel but has a more liquid consistency and a slightly sharp odor, with a dark color resembling worn-out tire rubber. RCO is a recycled fuel used as an alternative fuel for combustion devices that previously used diesel, gas, or residue.

Where RCO be Used?

Manufacturing Industry

Factories in industrial areas that use boilers, heaters, and electricity generators can use RCO as an alternative for energy source to reduce dependence on fossil fuels.

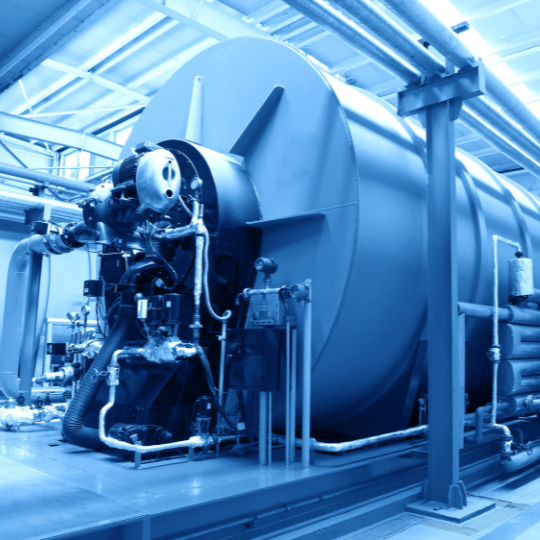

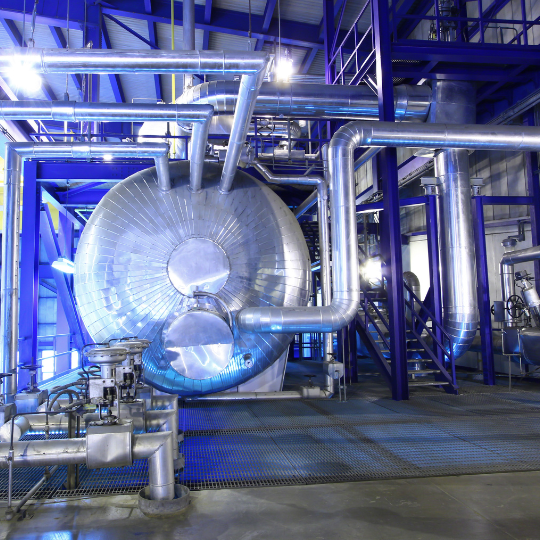

Boiler

RCO can be used as fuel for industrial boilers that require combustion to produce steam or hot water. These boilers are used in various industrial processes such as food processing, chemical production, and small-scale power generation.

Steam Boiler

RCO is used in steam boilers to generate steam that is utilized in various manufacturing processes. Steam boilers heated with RCO can be used in the food and beverage industry, textile mills, and chemical facilities for heating and sterilization processes.

Waste Management

Using RCO helps reduce the amount of used tires that are difficult to decompose and can pollute the environment. RCO has a high calorific value, meaning it can generate a significant amount of energy when burned, making it efficient as a fuel source. Utilizing alternative fuels like RCO can decrease dependence on non-renewable fossil fuels.

Incinerator

RCO is used as an alternative fuel for Incinerator engines, which are employed to burn solid waste and convert it into ash, gas, and heat. RCO tends to produce lower emissions compared to fossil fuels. It also has a high calorific value, making it an efficient fuel choice.

Shredder

A machine is used to break waste into small pieces to make it easier to process or recycle. By using RCO oil, which can be locally produced from available waste materials, fuel costs and dependence on fossil fuel imports can be reduced. The high caloric content of RCO oil makes it an efficient fuel for machines like shredders.

Why Use RCO

Energy Recovery

By

converting waste rubber into fuel oil, the energy that would otherwise be lost is

recovered and utilized. This can help offset the need for fossil fuels and

reduce energy consumption.

Environmental Benefits

Utilizing

rubber chemical oil as a substitute fuel can help reduce the environmental

impact associated with waste rubber disposal, such as landfill usage and the

release of harmful chemicals into the environment.

Resource Efficiency

Rubber

chemical oil provides a way to extract value from waste rubber materials that would

otherwise be discarded, thus promoting resource efficiency and waste reduction.

Versatility

Rubber

chemical oil can be used in various industrial processes, including as a fuel

source for boilers, furnaces, or in diesel engines with some modifications. Its

versatility makes it attractive for use in different sectors as a substitute

fuel.

Potential Economic Benefits

Depending

on the scale of production and market demand, the production and sale of rubber

chemical oil can offer economic benefits to businesses involved in waste

management and recycling.